Summary: This paper summarises the factors that affected the development of CW radio communication during the period up to 1918. It shows that most of the important circuits had been invented by 1914. The major technical factor affecting the successful development of CW radios for battlefield communication was the unavailability of robust radio valves: these did not become available until late in 1915 with the introduction of the French TM valve. Up until that time almost all radios were spark transmitters and crystal detector receivers.

Full version of the paper: Technical factors affecting CW radio communication in WW1 [pdf] Part 1 Part 2

Circuit development up to 1914

- Oscillator

Several people have claimed the invention of the valve oscillator but priority was given to Meissner who took out a German patent in April 1913 [21, 22]. Two important by-products of this invention were the heterodyne circuit and regenerative feedback (sometimes called reaction).

Significant improvements in oscillator design were made by Hartley and Colpitts, both working for Western Electric.

- The heterodyne

The heterodyne receiver was patented by Reginald Fessenden in 1901 [23]. The patent shows the use of two alternators at the transmitter connected on a common shaft and differing slightly in frequency. The outputs from these were each connected to separate antennas. At the receiver there was, likewise, two antennas and these were connected to coils wound on an iron core with a telephonic diaphragm at one end. In 1905 Fessenden applied for a further patent where he used one alternator in the transmitter and one in the receiver, the two frequencies being adjusted to produce an audible signal in the headphones [24].

A further improvement was made by Lee and Hogan in November 1912 when they used an alternator (or arc generator) in the receiver and a crystal detector [25].

The advantage of the heterodyne receiver was shown in the US naval trials from the Arlington station to the USS Salem, which commenced on 15 February 1913 [26, 27]. The trials compared the performance of the heterodyne receiver against that of a conventional crystal receiver and one using a ‘ticker’ to break up the incoming CW signal into short bursts.

A further improvement was made by Henry Round of the British Marconi Company with the invention of the Autodyne receiver which he patented in December 1913 [28]. The Autodyne was a self-oscillating mixer where the frequency of the oscillator was adjusted to differ slightly from that to the incoming signal. The valve used was the Marconi type C, soft triode.

- Regenerative feedback (reaction)

Edwin Armstrong had been seeking means to improve the sensitivity of the audion receiver which he had built as a student at Columbia University. He achieved this by regenerative feedback from the anode circuit to the grid circuit, the feedback being adjusted to just below the point of oscillation. This form of feedback became known as reaction. His circuit was witnessed by a notary on 31 January 1913.and he applied for a US patent later that year [29].

In Britain the Marconi engineer Charles Franklin patented his regenerative receiver circuit on 12 June 1913, four months before Armstrong. Franklin, it would appear, was the first person to note that the regenerative action increased the input impedance of the valve and thereby reduced the loading on the tuned circuit [30].

- RF amplifier

Although the triode valve had been invented by Lee de Forest at the end of 1906 it was not used successfully as an amplifier until 1911. The earliest recorded amplifier using the audion valve would appear to be that of Otto von Bronk, a Telefunken engineer who applied for a German patent on 2 September 1911 [31]. The circuit shown is of an RF amplifier (without grid blocking capacitor as used by de Forest in his detector and early attempts to produce an amplifier). The output from the valve is shown connected by an RF transformer to a crystal detector and telephone earpiece.

Conclusions

- Before the outbreak of WW1 in August 1914 many of the circuits to be used in later years for CW radio communications had already been invented, although most of these were still at an early stage of practical applications. These circuits include the radio wave detector, the oscillator, the heterodyne, the RF amplifier and regeneration.

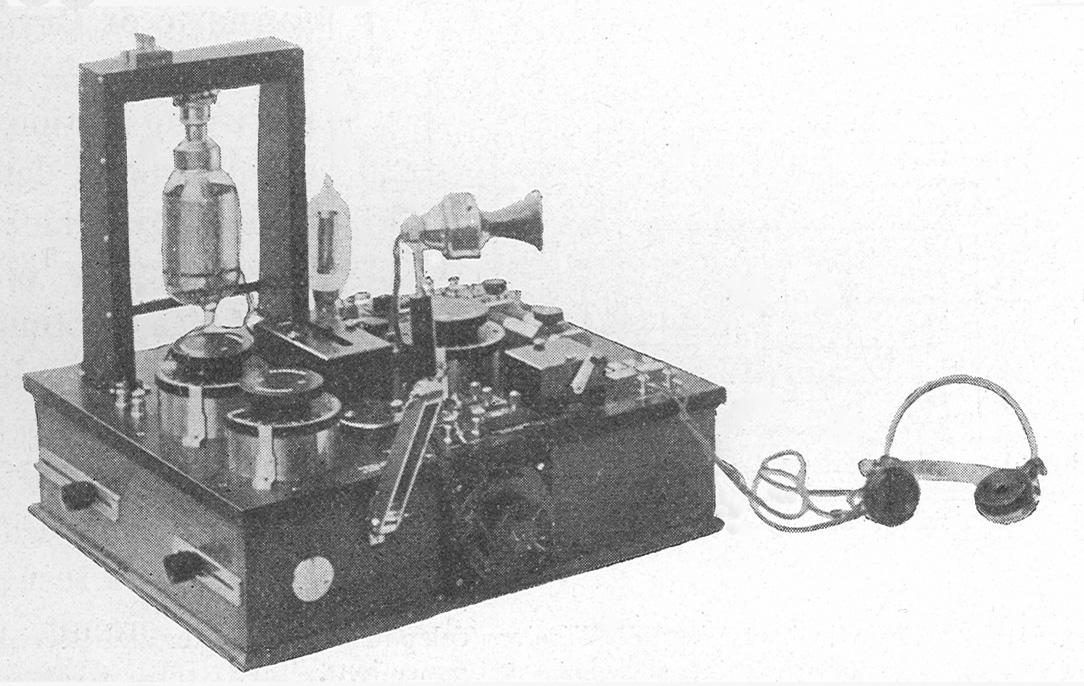

- The British Marconi Company embodied all of these in the Marconi Short Distance Wireless Telephone Transmitter and Receiver which was produced in 1914 and used on ship-to-shore trials.

- There were few valves available in 1914 for use in radio equipment. The de Forest audion was erratic in operation, fragile and had a short filament life. The Marconi soft valves, the C and T, were produced in 1913 and used in the radio mentioned in the previous paragraph. The C was a receiver valve and the T a transmitter valve. Both of these were difficult to manufacture and not suitable use on the battlefield. Apart from this the T valve required a power of 6-volts, 4-amps for its filament which meant very frequent replacement of the storage battery. Also an HT of several hundred volts was required.

- One important application of the Marconi C valve was in direction finding receivers and these continued to be used throughout the War until suitable hard valves became available from 1916.

- Until more robust valves became available the only way to communicate by radio from the trenches was by spark transmitters and crystal detector receivers. The transmitted signal from the spark transmitters was noisy and rich in harmonics which were spread over a wide spectrum. This meant that the radios had to be widely separated to prevent mutual interference.

- Even so it might have been possible to deploy a small number of an improved version of the Marconi Short Distance Wireless Telephone Transmitter and Receiver for use in Headquarters and some vehicles, but this did not happen.

- The situation changed dramatically with the introduction of the French TM valve in the early months of 1916. These valves were not well suited for use as RF amplifiers, except, maybe, at frequencies below 600 kHz. They were, however, well suited for use as radio detectors and audio amplifiers, not just in radios but also for the amplifiers required for the power buzzers. A valve more suitable as a detector and, possibly, as an RF amplifier was the Marconi Q. However, this valve proved difficult to manufacture in large quantities.

- It is well documented that there had been a reluctance in the Army to adopt radios and there was too much reliance on line communication, even though the cables were being constantly destroyed. Some of this reluctance was probably due to the problems of using spark transmitters in the trenches which were cumbersome and required skilled operators for the Morse transmissions. Their aerials also marked the position of the radios for enemy gunfire.

- The most obvious places for CW radios were in aeroplanes, motor vehicles and tanks and there should have been a concerted programme to design and manufacture radios for these.

- For use in trenches the requirement would have been for portable radios and these would have been required in large numbers during the last two years of the War.

- It is difficult to assess how many radios could have been produced by the British and French in the last two years of the War. The manufacturing companies would have been short of skilled labour and engineers because of the enormous toll of lives that had taken place, particularly of those men in the Signal Service.

References

21. Tucker, DG, ‘The history of positive feedback’, The Radio & Electronic Engineer, 42, No. 2, February 1972, pp.69–80.

22. Meissner, A, German patent, appl. 10 April 1913.

23. Fessenden, RA, US patent, 706,740, appl. 28 September 1901.

24. Fessenden, RA, US patent, 1,050,728, appl. 27 July 1905.

25. Lee, JW & Hogan, JL, US patent 1,141,717, appl. 16 November 1912.

26. Howeth, Capt. LS, History of Communications-Electronics in the United States Navy. Washington; 1963, pp.182–4.

27. Hogan, JL, ‘The heterodyne receiving system and notes in the recent Arlington-Salem tests’, Proc IRE, 13, July 1913, pp.75–102. (Note: Hogan worked for Fessenden at NESCO).

28. Round, HJ, British patent 28,413/13, appl. 9 December 1013.

29. Armstrong, EH, US patent 1,113,149, appl. 29 October 1913.

30. Franklin, C, British patent, 13,636/13, appl. 12 June 1913.

31. Von Bronk, Otto, German patent, 271,059, appl. 2 September 1911.